Case Study 01

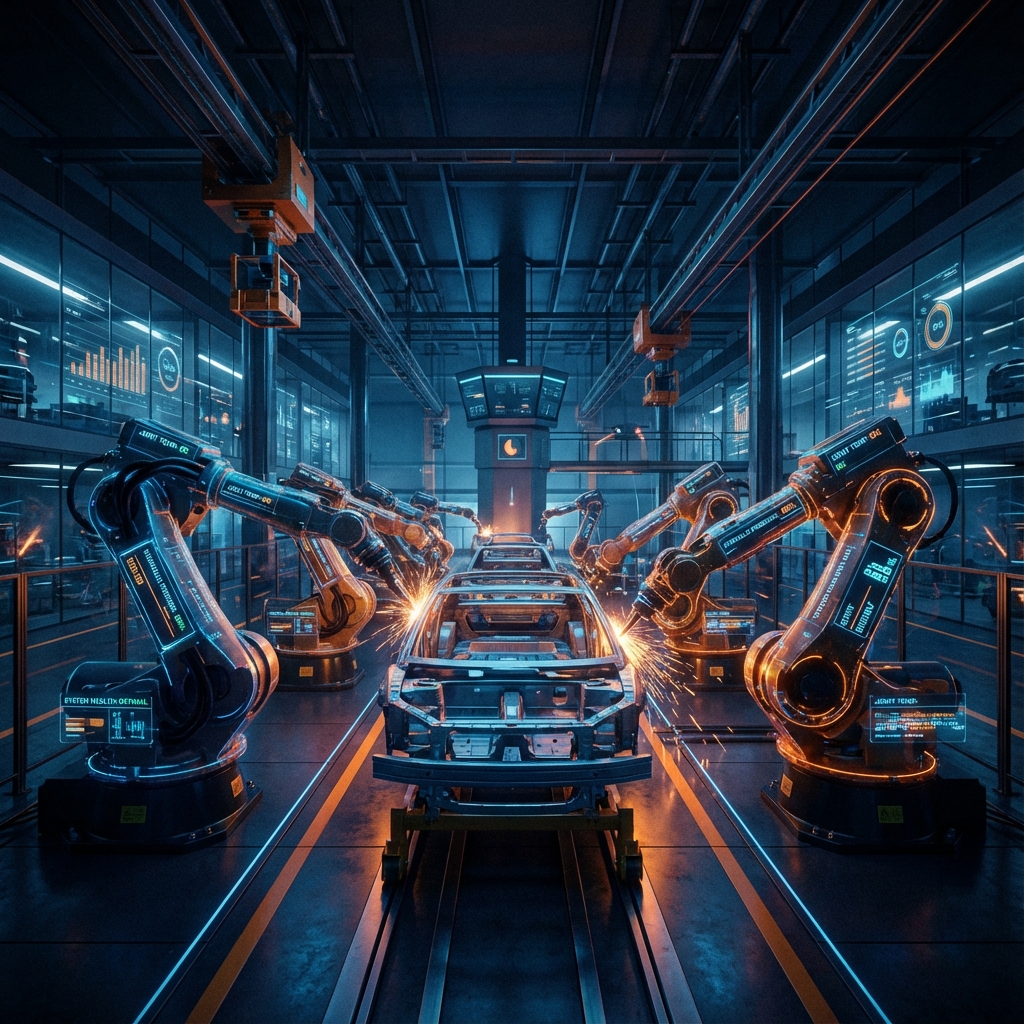

Industry 4.0 Smart Factories

Transforming fragmented shop-floor operations into connected, data-driven manufacturing environments - where every machine heartbeat becomes an actionable insight.

The Context

Siloed Data Across the Shop Floor

A mid-to-large manufacturer operated multiple production lines with limited real-time visibility into machine health, downtime causes, and throughput variability.

Critical production data existed across PLCs, SCADA systems, and maintenance logs - but was siloed and reactive. Unplanned downtime resulted in lost production hours and high maintenance overhead.

The Friction Point

Reactive Maintenance Is a Losing Strategy

No real-time visibility into machine health or failure indicators. Maintenance activities were reactive and high false alarms created alert fatigue.

High false alarms creating alert fatigue for operations teams.

Reactive, calendar-based maintenance driving unnecessary costs and missed failures.

Spare parts planning lacking data-driven forecasting, leading to overstock and shortages.

Our Approach

Predictive Maintenance Foundation

IoT Sensor Instrumentation

Retrofitted legacy equipment with vibration, temperature, and load monitoring sensors to capture machine heartbeats - creating a continuous digital pulse across every production line.

Edge-Level Data Processing

Deployed local gateway algorithms to analyze high-frequency sensor data in real time, reducing latency and bandwidth dependency while enabling immediate anomaly detection at the source.

Predictive Trend Analysis

Implemented centralized data ingestion and threshold modeling to detect failure patterns weeks in advance, integrating directly with CMMS systems for automated work order generation.

Measurable Results

Impact on OEE

Unplanned outages eliminated

Improved response times

Data-driven inventory

Asset uptime gains

Case Study 02

Digital Engineering & Simulation

Simulating production realities to optimize throughput before physical execution - reducing commissioning time and eliminating costly prototyping cycles.

The Context

High-Cost Commissioning Cycles

A manufacturing engineering team faced high costs and delays during line reconfiguration, equipment layout changes, and commissioning of new production workflows. Physical prototyping was expensive, time-consuming, and carried safety risks.

The Friction

Long commissioning cycles for new production lines.

High dependency on physical prototypes.

Limited ability to test failure scenarios safely.

Operator training only possible after deployment.

The Solution

Digital Twin Simulation Platform

We developed a physics-based 3D digital twin of production lines for simulation of throughput, bottlenecks, and material flow.

Physics-Based Twin

Rigorous 3D simulation of production physics, replicating real-world behavior with engineering accuracy.

Throughput Sim

Identifying bottlenecks and optimizing material flow before execution on the physical production floor.

Operator Training

Virtual training environments using real process data, enabling hands-on learning without production risk.

Measurable Simulation Impact

Full Spectrum

Manufacturing Capabilities

Questions

Manufacturing AI FAQs

Smart factories use IoT sensors, edge computing, and AI analytics to create real-time visibility across the production floor. This enables predictive maintenance (reducing unplanned downtime by up to 40%), automated quality inspection, and dynamic scheduling - resulting in 15-25% overall efficiency gains.

AI-powered computer vision systems inspect products at line speed with sub-millimeter accuracy, detecting defects invisible to the human eye. Combined with statistical process control, these systems reduce defect rates by up to 90% and eliminate costly manual inspection bottlenecks.

Predictive maintenance uses vibration, temperature, and load sensors combined with machine learning models to detect early signs of equipment degradation. By analyzing trends and thresholds, it predicts failures days or weeks in advance - replacing reactive, calendar-based maintenance with data-driven interventions.

Yes. AI models analyze demand signals, supplier lead times, logistics constraints, and inventory levels to optimize procurement, production scheduling, and distribution. Manufacturers typically see 20-30% reduction in inventory costs and 15% improvement in on-time delivery.

Digital twins are physics-based virtual replicas of production lines, equipment, or entire factories. They simulate throughput, test layout changes, validate new processes, and train operators - all without disrupting live production. Companies using digital twins report 30% faster commissioning and significant reductions in prototyping costs.

Let's Build Smarter Manufacturing Systems

Every manufacturing operation has unique challenges. We have the expertise and case studies to solve them.